Conveyors are used in various industrial environments. Any business that handles goods could benefit from an effective conveyor system. While some conveyors can be directly bolted to the floor, many others require a support system. The different types of supports offer distinct advantages:

Weld-Up Supports

Pros:

- Carry less raw material cost & less hardware cost.

- More structurally sound than bolt-up.

Cons:

- Field weld labor is harder to find and carries a high expense.

- Field welding requires special safety procedures and permits.

- Adjustments must be made by cutting and re-welding whenever field modifications are required.

- New welds in the field require an additional operation of wet paint to protect bare metal from corrosion and for aesthetics.

Bolt-Up Supports

Pros:

- Designed so that manual adjustments can be made on the fly.

- Damaged parts in the field can be easily swapped out and replaced.

Cons:

- Additional hardware is required. If lost or misplaced onsite, can cause delays and/or issues.

Overall Stock MHS can offer both options per the request of the customer. We’re here to provide the best solution to fit your needs.

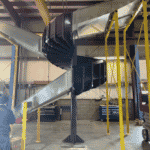

- Chute Bolt-Up Supports

- Chute Bolt-Up Supports

- Conveyor Bolt-Up Supports

- Chute Weld-Up Supports

- Chute Weld-Up Supports

Let’s take a look at several types of supports for conveyors and chutes:

Tripods

Tripods are a type of conveyor support that is generally used for systems that have low weight requirements. They're easy to set up and work well with portable conveyors.

Tripods are very versatile as they can be used as either a conveyor or chute support. They're also suitable for both straight and curved sections of conveyors.

H Stands

H Stands are available in a range of styles and capacities. In terms of weight requirements, they range from light duty to heavy duty, so you can customize for the size and weight of the goods your business handles. Heavy-duty H Stands are typically a type of welded conveyor support, as they provide more strength.

An H stand is most commonly a bolted conveyor support that is secured to the floor. You can also opt for castered H stands if there are any sections of your conveyor system that you need to be able to move easily.

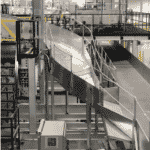

Multi-tiered

Multi-tiered supports are less common but can be incredibly convenient in certain environments. They allow for more than one conveyer to run above another. They can typically be used with both gravity roller and skatewheel conveyors.

These are ideal in environments with space limitations. You can run multiple conveyors while minimizing the amount of floor space used. These supports are typically made for two conveyor levels, but it is possible to add more if needed.

Low-Profile

Some conveyor systems are fitted at ground level, but these can come with limitations. If you want to maintain this type of conveyor, you can add low-profile supports. With these, you can raise the conveyor slightly, and add slopes if necessary.

You can purchase a single pair, or several pairs, depending on what you want to do with your conveyor system. They're typically available at as low as 1", and can range to around 6".

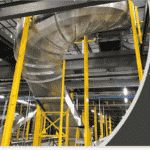

Ceiling Hanger

For certain applications, other types of supports don't raise conveyors high enough. In this case, you may want to opt for ceiling hangers. As the name suggests, they hang down from the ceiling — keeping the floor space completely free.

It's worth noting that ceiling hangers generally have lower weight capacities than other types. It's also a good idea to use conveyor guarding with ceiling supports to maintain safety.

Supports for Conveyors

With all the different types of supports that are available for conveyors, it can be difficult to know which type would be best for your business. At Stock MHS, we specialize in designing and supplying custom solutions for the material handling industry. We can develop the perfect system for your business, and help you settle on the most ideal support types.

Recent Comments